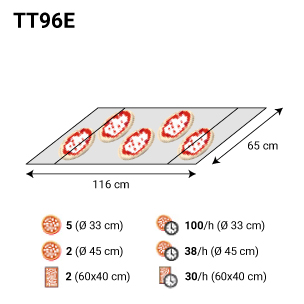

SerieT - TT96E Conveyor

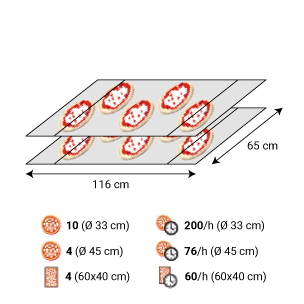

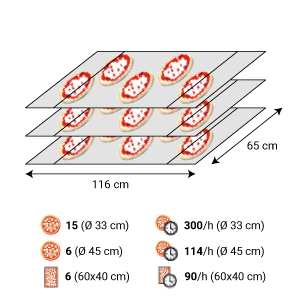

TT96E, the electric modular conveyor oven, is composed of one or more stackable baking chambers and an optional stand.

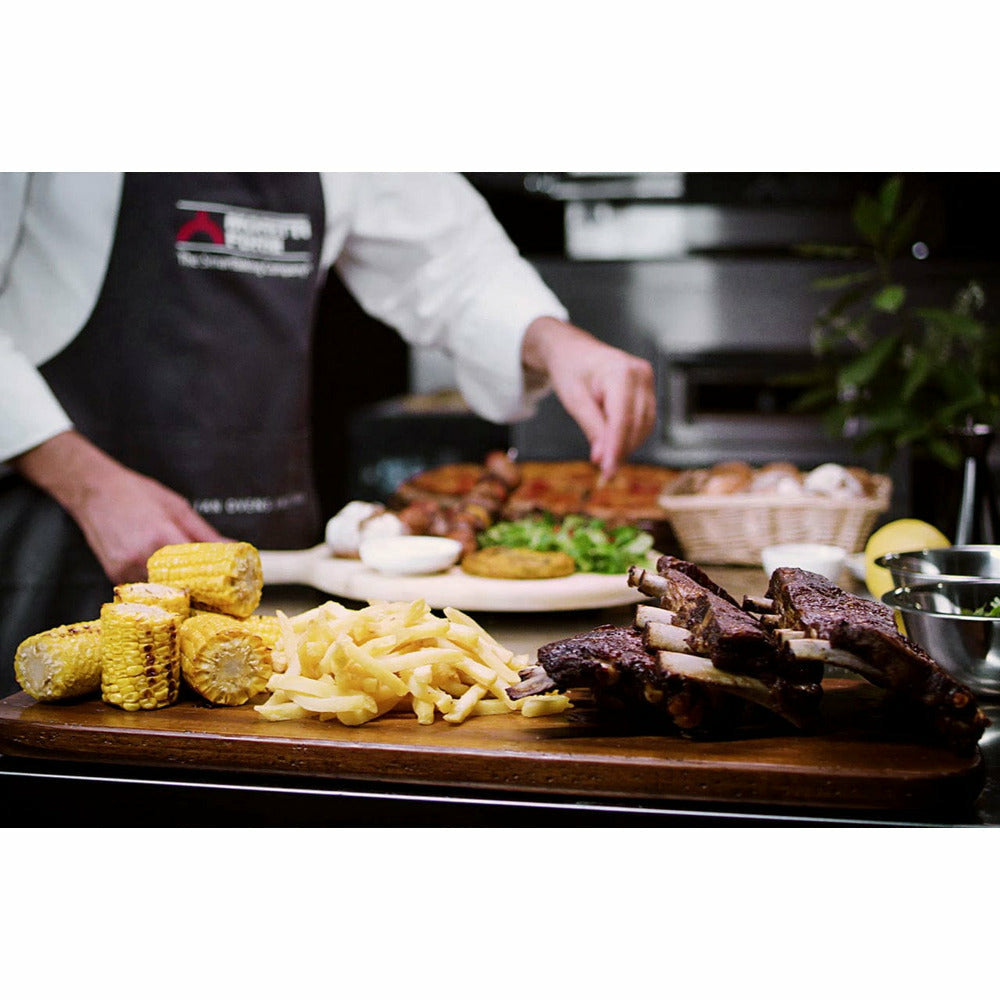

During baking, the product is placed on the conveyor belt and passes through two flows of hot air: impingement technology, the best system for heat distribution in the whole baking chamber for perfect baking of pizza, pastry, bakery, and gastronomy.

Management of needed power is automatic according to the load. The power control of ceiling and floor is independent and managed by two probes. The conveyor speed is adjustable. Efficiently insulated and isolated, the external surfaces are cool even during use. The baking chamber maximum temperature is 320°C (608°F).

Features

Dual-Temp Technology

Independent control of the ceiling and floor temperatures to calibrate the baking of gastronomy products perfectly.

Quadra-Temp Technology

With TT96E e TT98E models it is possible to set and differentiate up to 4 temperatures: 4 probes, placed at the beginning and at the end of both ceiling and floor, monitor and manage every stage of baking for a punctual heat calibration.

Dual-Flow Technology

Gas models manage warm airflows separately in order to calibrate the heat according to baking needs.

Eco-Standby Technology

The smart function to save energy. Set the oven on standby during work pauses, it will be ready to be used with a click!

Adaptive-Power Technology

serieS regulates real-time and independently needed power according to the quantity of product placed in the baking chamber by using only the minimum energy required to perfectly bake without waste.

Best-Flow System

A special system diverges and conveys warm airflows avoiding uncontrolled air recycling near the products, during baking. Uniform baking in all baking areas!

Weekly Power-On Timer

SerieT allows programming weekly power on timer to find the oven always ready to bake. Save time and increase your staff’s efficiency.

Cool-Around Technology

Heat is kept inside the baking chamber and the external surfaces are cold for better livability and safety in the workplace.

Remote-Master Technology

The exclusive function to create or modify programs, check baking settings, receive communication about service records from the oven. *Optional to be purchased separately*

Serial Wifi Module

It allows downloading software updates and using the latest available version.

Specifications

Downloads

|

|